The first step of any successful floor application depends on the surface preparation. A clean and sound surface is necessary to establish a strong bond between the substrate and the subsequent flooring layer (e.g. resin coating). The substrate needs to be clean and dry, without debris, cracks or holes. If there are existing cracks and holes, ensure proper repair of the cracks and holes by using epoxy mortars or epoxy resin. For floors that are damp (not constantly wet substrate), an option is to treat it with a moisture barrier coating or epoxy mortar. Any existing loose coatings must be removed completely and sanded. Existing floors must be sanded until there is no gloss to the existing floor surface - a glossy floor will not allow the subsequent floor coatings to adhere well, then vacuum to remove dust before applying any floor coatings. Uneven floors with high spots need to be grinded or fill low spots to level the floor.

The purpose of surface preparation is to:

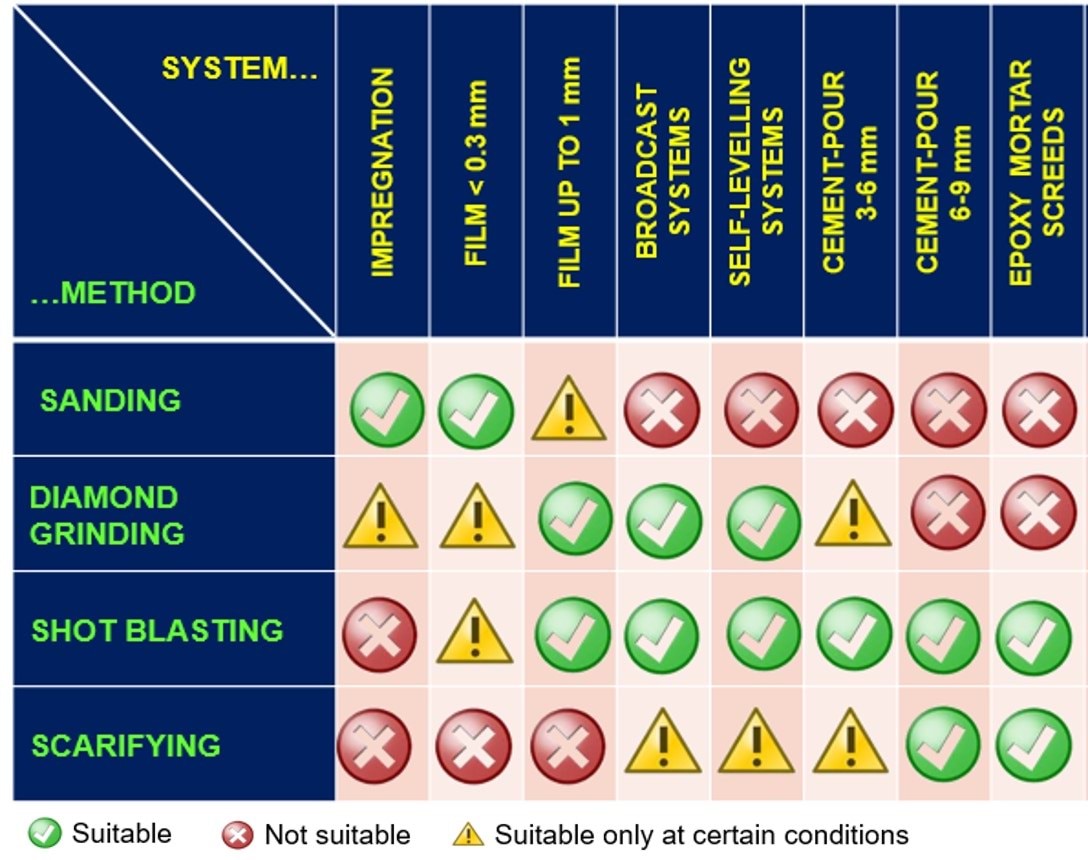

There are four types of surface preparation methods. The method chosen largely depends on the following factors:

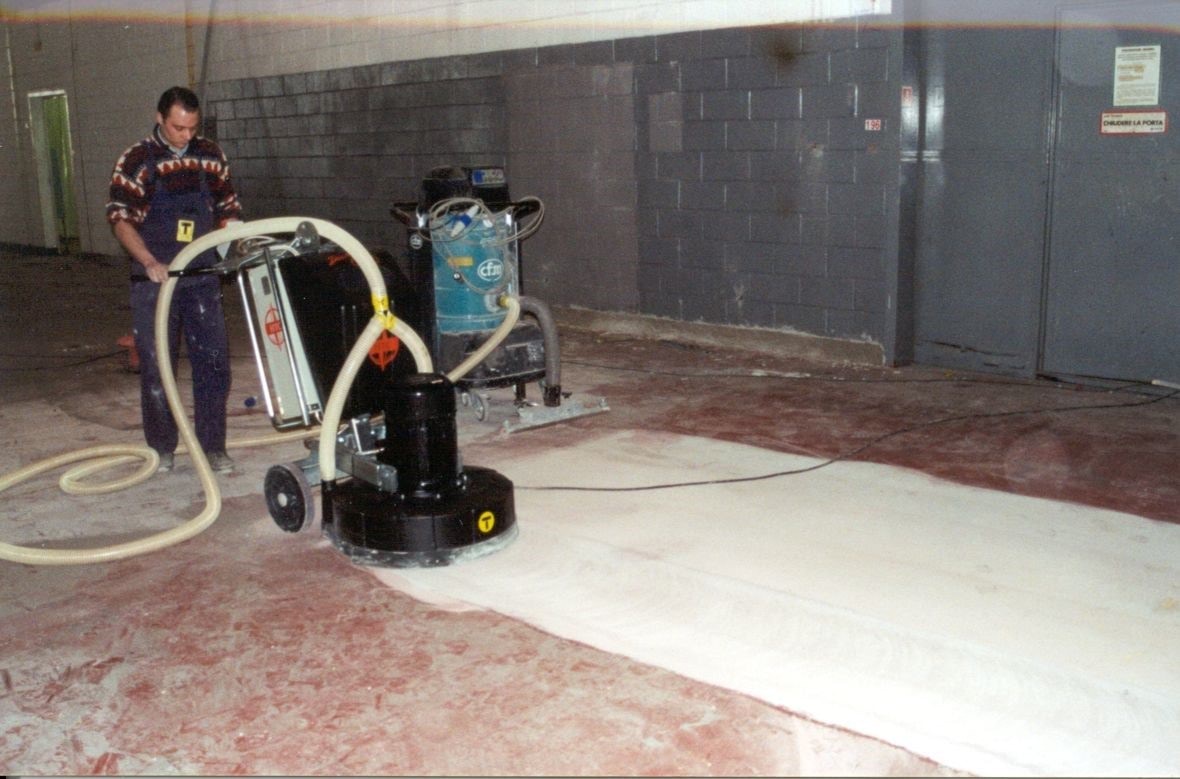

Sanding/Grinding can be done on new and/or smooth cementitious surface that is dry and clean. It removes cement laitance and dust, and lightly open surface porosity without roughening the surface. This method is suitable for impregnation treatments and for floor coatings subject to low traffic and exposures, for old and clean resin coating before application of other maintenance layers. After sanding, vacuuming is required to remove fine dust which plugs the pores of the substrate. Pores are beneficial for creating a strong bond to the subsequent floor layer.

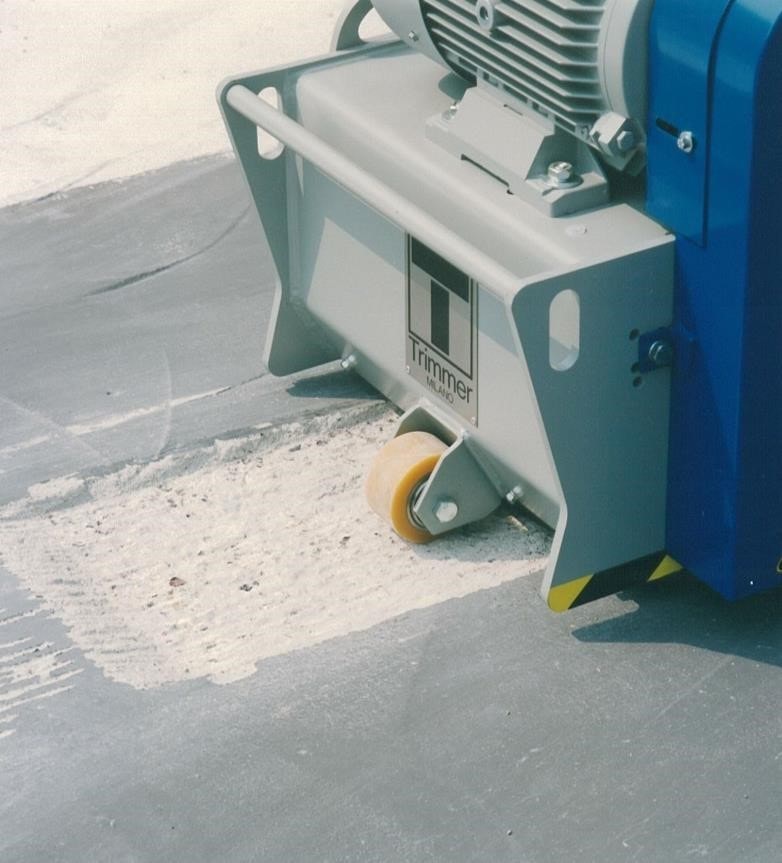

Diamond wheel grinding helps remove a very thin layer of surface that could be weak or contaminated. Besides, it opens surface porosity and lightly roughen the surface. This method can be performed on new and old cementitious substrates, tiles and stones, surfaces that are lightly contaminated or comes with a very thin old coating that needs to be removed. It is suitable for broadcasting and applying self-levelling systems subjected to low to medium traffic and exposures.

Shot blasting can be used on new and old substrates with surfaces lightly contaminated or have a very thin coating that need to be removed. It works by removing loose and friable parts, surface contaminants, opens up surface porosity and roughen the surface. This method is ideal before broadcasting and self-levelling systems, resin mortar screed and CPU systems subject to medium to high traffic exposure.

Scarifying works perfectly on new and old substrates, when the surface is weak or contaminated in depth or requires the existing coating to be removed. The scarifying machine comes with different number, size and hardness of steel disks in various rollers that can remove existing coatings or screeds. It removes a few millimeters of unsuitable substrate and reaches a sound and clean substrate. This method works for concrete, cementitious screeds and old resin floor removal. It is suitable for high thickness broadcast and self-levelling systems, repair mortar screed, CPU systems subjected to high traffic exposure.

Contact Mapei Singapore for consultation on your project needs.

____

About Mapei:

Founded in Milan since 1937, Mapei is today a world leading producer of adhesives and complementary products for the laying of all types of floor, wall and coating materials. Mapei’s specialty lies in products for ceramics and stone materials, among other product lines. Mapei’s adhesives for tiles and stones are certified according to international standards and are SGBC certified. Experience proven by numerous notable projects worldwide.