Modified bitumen for Tirana International Airport Nënë Tereza, Tirana (Albania)

Mapei technology deployed for the refurbishment of the runways, taxiways, and aprons.

To upgrade the paving at Tirana airport, Mapei supplied elastomeric polymers to produce polymer-modified bitumen. This enabled the bitumen to be produced in the quantities required, directly at the production plant, and to obtain binders with excellent elasticity and stability over time using normal, locally-sourced bitumen as the base material.

Mapei technology deployed for the refurbishment of the runways, taxiways, and aprons.

Airport paving is designed to provide adequate support for loads transmitted by aircrafts and, at the same time, to have a surface that is as solid and even as possible and resistant to wear.

Deterioration of paving on runways, entry and exit areas of runways, taxiways and aprons has become a major problem due to an increase in air traffic, ageing of materials and, in some cases, insufficient or poor maintenance.

The level of air traffic at Tirana International airport Nënë Tereza has increased considerably in recent years as a result of there being more connections with other European and non-European cities.

An increase of the number of aircrafts in circulation has led to an increase in the loads acting on the paving of the airport.

All this underpins the importance of carrying out periodical maintenance work to extend the service life of paving and to prevent the risk of surfaces losing their efficiency over the years.

UPGRADE AND REFURBISHMENT OF THE RUNWAYS AND TAXIING AREAS

Tirana International Airport (TIA) launched an important project called "Airfield 2020", which consists of refurbishing the runways and taxiing areas on the ground used by the aircrafts.

Apart from these areas, other work was carried out to partially restore the paving for the aprons used for disembarking and boarding passengers, loading and unloading goods, carrying out refuelling and parking and maintaining aircrafts.

THE AIRFIELD 2020 PROJECT

The "Airfield 2020" project was split into different phases. The first phase, which has now been completed, was the complete reconstruction of the paving for taxiways W and B, for a total length of 1.5 km and a width of 45 m, in compliance with international standards.

The first phase also included the complete refurbishment of certain areas of the bituminous conglomerate for the aprons.

The second phase of the project is a complete rebuild of the paving for the runways.

FIRST PHASE: THE TAXIWAYS

The first part of the project included the following work on the taxiways:

- demolition of the old paving;

- removal of the subbase course of the paving;

- digging out new foundations;

- positioning new drainage channels;

- rebuilding new paving;

- installation of new ground lighting.

The work carried out to upgrade the paving included refurbishing the high modulus binder layer (thickness 7 cm) and the hard-modified wearing course layer (thickness 5 cm).

THE DESIGN OF THE STRATIGRAPHIC LAYOUT

The design of the stratigraphic layout of the paving had the following layers:

- Cement stabilized foundation layer

- Bituminous conglomerate base course made from traditional 50/70 bitumen and aggregates up to 32 mm in diameter (thickness: 10 cm);

- A second bituminous conglomerate base course made from traditional 50/70 bitumen and aggregates up to 22 in mm in diameter (thickness 8 cm);

- Bituminous conglomerate binder layer made from modified 25/55-60 bitumen and aggregates up to 22 mm in diameter (thickness 7 cm);

- Bituminous conglomerate wearing course layer made from modified 45/80-65 bitumen and aggregates up to 16 mm in diameter (thickness 5 cm).

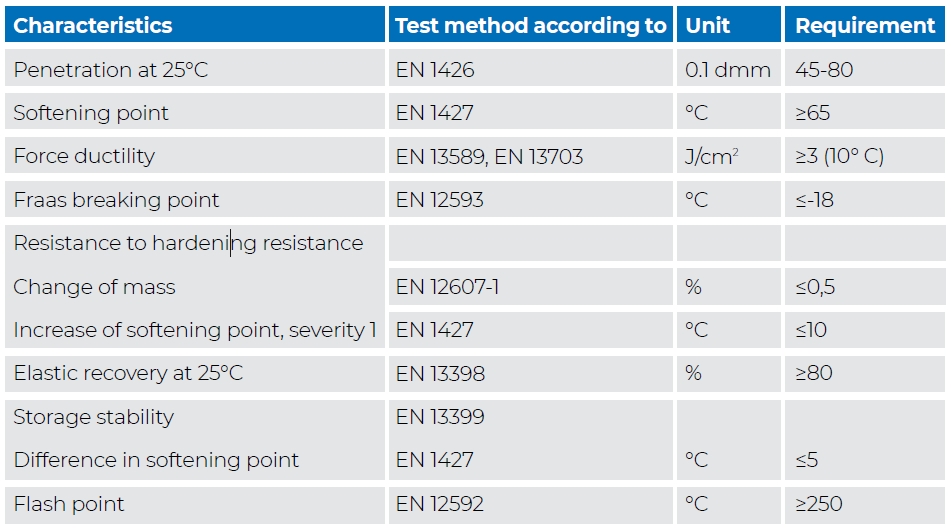

For more details on the technical specifications of the modified bitumen used for the binder and wearing layers, please check the extract of the tender document with the required properties and characteristics.

BITUMEN-MODIFYING POLYMERS

Right from the beginning of the project and then throughout the carrying out of validation tests, Mapei and its Research & Development Laboratories worked in close partnership with the Euroteorema Group, a leading contractor of bituminous conglomerate road surfaces, and with the STS Mobile Laboratory.

Mapei supplied special polymers to transform traditional bitumen into modified bitumen, as per the Technical Specifications, to be used as a binder in the binder layer (PMB Hard) and wearing course layer (High Modulus PMB). In the first part of the project, Mapei supplied MAPEI E-SBC2, a special mixture of elastomeric polymers to modify bitumen for the binder and wearing course layers. This ensured the following advantages:

- It was possible to make modified bitumen meeting the requirements of the technical specifications directly at the production facility, without having to use a colloidal mill, rather than importing the modified bitumen from abroad.

- No need to store the modified bitumen for long periods, which would have led to the bitumen oxidation and a partial loss of its properties. It was possible to produce the amount needed as and when required.

- The binder was produced using normal, locally sourced bitumen and featured excellent elasticity and stability over time.

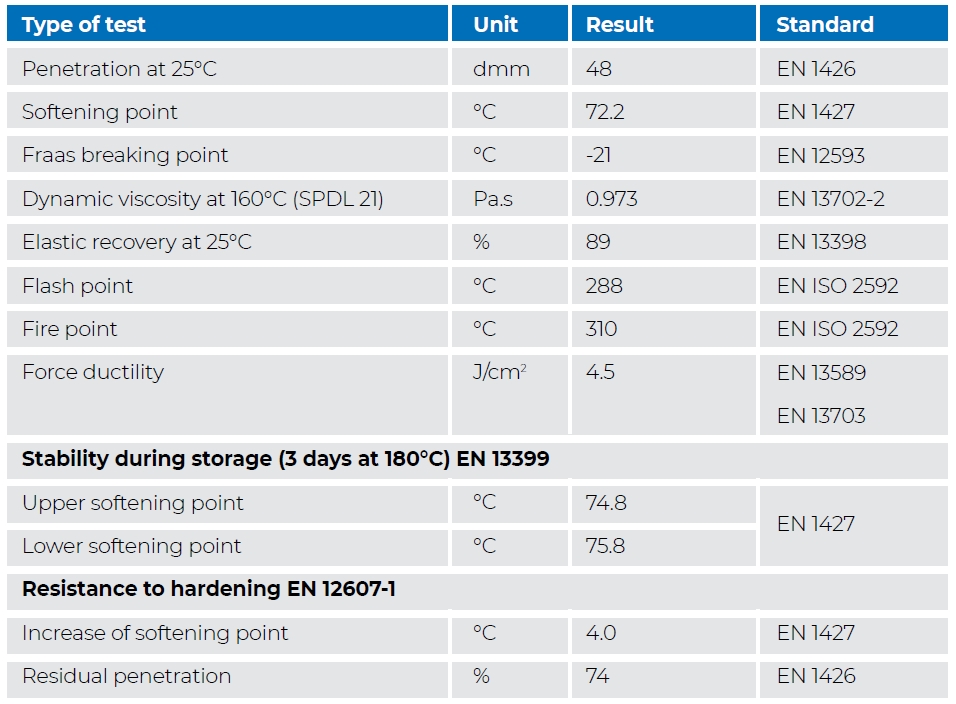

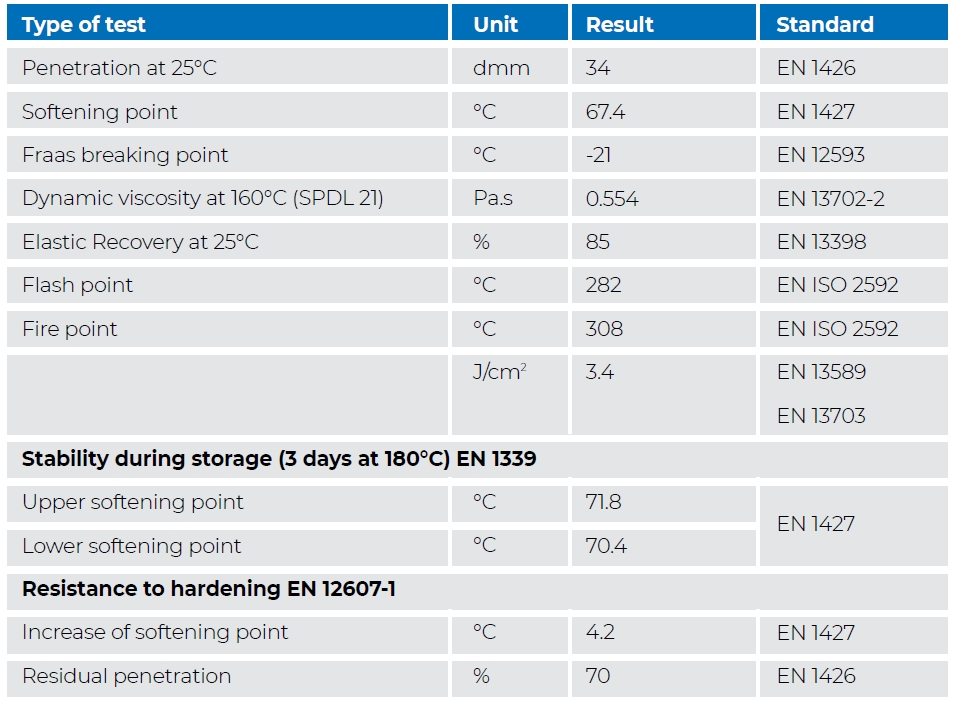

Take a look at the results of tests carried out on samples taken on site of hard and high-modulus modified bitumen.

POLYMERS FOR MODIFIED BITUMEN

Using modified bitumen allows you to achieve numerous advantages when constructing flexible paving for motorways and airports.

Improving the viscoelastic properties of bituminous conglomerate and the hardness of paving leads to a considerable reduction in the total cost of its service life.

Modified bitumen is made by adding special polymer modifiers so that it meets requirements such as resistance at low and high service temperatures and an increase in the elastic recovery, which makes paving less susceptible to cracking. These polymers have a positive effect on many other properties of traditional bitumen, such as drastically reducing the risk of oxidation, one of the most common problems that limits the service life of paving.

The advantages of using modified bitumen in bituminous conglomerate may be summarised as follows:

- less susceptible to daily and seasonal temperature variations

- higher resistance to deformation

- higher resistance to ageing

- higher resistance to fatigue

- higher level of adhesion between aggregates and binder

- prevents cracking phenomenon

Modified bitumen technology has been around for some time and is available from large petrochemical companies where this type of bitumen is produced on an industrial scale.

Only more recently, however, have special polymers been developed, which are added to traditional bitumen in relatively simple production plants. This has made possible to make modified bitumen even when there is no access to a special production plant with a colloidal mill.

Mapei has developed a series of special polymers which are produced by means of a special chemical process. This process combines different molecules of selected elastomers in granulated powder form, combined with recycled rubber and other specific raw materials, so that they disperse very efficiently throughout the virgin bitumen and optimise the performance properties of the resulting polymer-modified bitumen.

Mapei technology enables modified bitumen to be produced according to specific characteristics and properties required to comply with the most severe technical specifications. What is more, this technology may even be applied in geographical areas that are difficult to reach and at a relatively low cost for modifying the production equipment needed for the process.

.jpg?sfvrsn=907b4f70_6)

.jpg?sfvrsn=917b4f70_6)