Re-Con Zero Evo: sustainable concrete with recycled aggregates

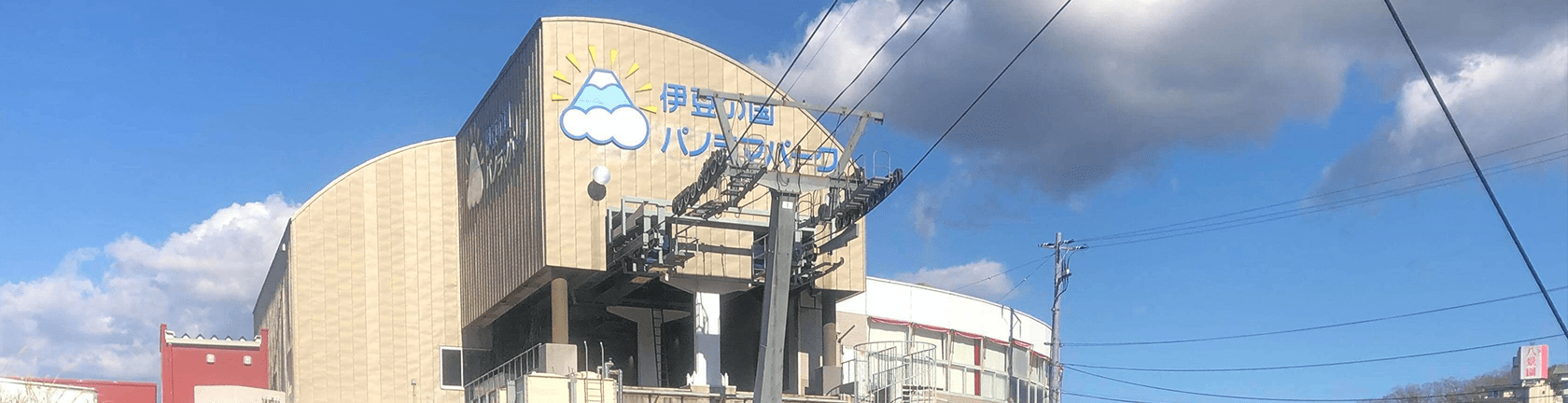

Returned concrete was used to build a new carpark at Panorama Park in Izu Nagaoka, Japan.

Returned concrete was used to build a new carpark at Panorama Park in Izu Nagaoka, Japan.

The Izu peninsular overlooks the Pacific Ocean around a hundred kilometres to the south of Tokyo and forms a division between the Bay of Suruga and the Bay of Sagami. It was designated a protected area and geological park by Unesco in 2018 and is characterised by its hills and features of volcanic origin covered by rich, lush vegetation.

From Izu Nagaoka, a town with around 50,000 inhabitants, you can take the Panorama Park cable-car to the summit of Mount Katsuragi, where you can admire a view of Mount Fuji on the right and the Bay of Suruga on the left.

Thanks to these particular characteristics the summit of Mount Katsuragi attracts tens of thousands of tourists every year and, with the Izu peninsula being the site for the indoor cycling events of the 2020 Olympic Games, the number of visitors is expected to increase.

In preparation for the event, the company that manages the cable car decided to extend the carpark at the departure station by 1,500 m2.

The extension to the carpark was made from Roller-Compacted Concrete (RCC), an ultra-dense type of concrete which is placed using the same equipment as for asphalt road surfaces. By using this kind of concrete, there is no need to use formwork or steel reinforcement in order to produce concrete surfaces which, apart from requiring a very simple construction technique, also have particularly high mechanical properties and durability.

The mix for the concrete (cement, aggregates and a small amount of water) has to be prepared in special mixing units that disperse the water evenly throughout the mix so that it forms a consistency similar to that of damp earth.

The fresh concrete is then transported to site on trucks where it is offloaded, spread out and distributed in layers of between 10 and 20 cm thick.

Compaction, made by vibrating rolls, is the most important phase in the production of RCC because it has to guarantee the correct density, strength, flatness and homogeneity of the concrete surfaces.

The surfacing then has to go through a curing process to ensure its mechanical characteristics develop correctly.

AN INNOVATIVE PROCESS

The need to safeguard the environment around the cable-car station meant all the work carried out had to have the minimum impact on the environment and the maximum use of recycled materials.

This is why it was decided to make the surfaces for the new carpark using RCC with low cement content and only recycled aggregates from the recovery process of returned concrete, that is, concrete that hasn’t been used on site and is returned to the production plant while still fresh.

Returned concrete represents the largest amount of residual material at the concrete manufacturing plant and accounts for around 3% of the total production.

Disposing of returned concrete in landfill sites has a heavy impact on the environment which may be expressed in terms of “equivalent” CO2 - the gas mainly responsible for global warming - with an impact of 267 kg of CO2 per cubic metre of concrete.

But now, thanks to the use of RE-CON ZERO EVO, the revolutionary additive developed in the Mapei Research & Development laboratories, it is possible to recover all returned concrete by transforming it, in just a few minutes, into an aggregate mix perfectly suitable to be used again to produce new concrete.

When RE-CON ZERO EVO is added to returned concrete in a mixer truck, or in any other suitable mixing system, in the space of just a few minutes the special additives of the product absorb any free water present and “dry” the concrete, transforming it into a mix of aggregates without generating any waste.

The advantages of this innovative product are clear: the production of aggregates from returned concrete enables the acquisition of natural aggregates to be reduced by a corresponding amount, which in turn limits the depletion of raw materials from natural sources, and it also completely eliminates the use of landfill sites which, in turn, further reduces its impact on the environment by reducing the amount of CO2 produced.

The new surfaces for the carpark at Panorama Park was carried out by the Nagaoka Ready-Mixed Concrete NR-MIX company, a distributor of RE-CON ZERO EVO in Japan, on behalf of the client, Dainici Izu no Kuni City Panorama Park. Overall, 170 m3 of RCC was placed, with a dose of just 69 kg/m3 of cement and 2,220 kg/m3 of recycled aggregates, which was achieved thanks to the use of RE-CON ZERO EVO.

Construction of the new carpark for the Panorama Park cable-car in Izu Nagaoka required the use of around 380 tonnes of recycled aggregates from returned concrete, thereby avoiding having to take the same amount of returned concrete to landfill sites, for a saving of around 100 tonnes of CO2 emissions.

All this was made possible thanks to the use of RE-CON ZERO EVO, the admixture by Mapei enabling the sustainable recovery of returned concrete.