Polyglass USA

Waterproofing membranes with a focus on innovation and sustainability.

Polyglass U.S.A., Inc. manufactures bitumen and synthetic waterproofing membranes for low- and steep-slope roof applications that are distributed across the whole of the American territory. But the story of Polyglass USA has its roots in Italy. In the 1960s the three Zanchetta brothers, Luigi, Romano and Antonio, who at the time were working in the roofing sector, founded “Superasfalti Zanchetta”, a company specialised in waterproofing solutions, and began manufacturing on a small scale.

In 1969, they started producing on a more industrial scale and the Polyglass brand was launched. This was just the start of an expansion process and in the 1980s they entered the United States market, opening their first facility in 1989 in the state of Nevada (in Fernley), which was followed in 2000 with a facility in Hazleton (Pennsylvania) and then another in Winter Haven (Florida) in 2006.

Polyglass was acquired by the Mapei Group in October 2008.

The head office of Polyglass USA is in Deerfield Beach, Florida, where there is also a Research & Development Centre. Over the course of the last few years, new facilities in Phoenix (Arizona) and Waco (Texas) were added to the portfolio of sites mentioned above.

Today, Polyglass USA has 260 employees and a turnover of more than 200 million dollars.

Apart from their Polyglass Spa facilities in Italy, they also have a subsidiary in the UK.

CONTINUOUS INNOVATION AND RESEARCH

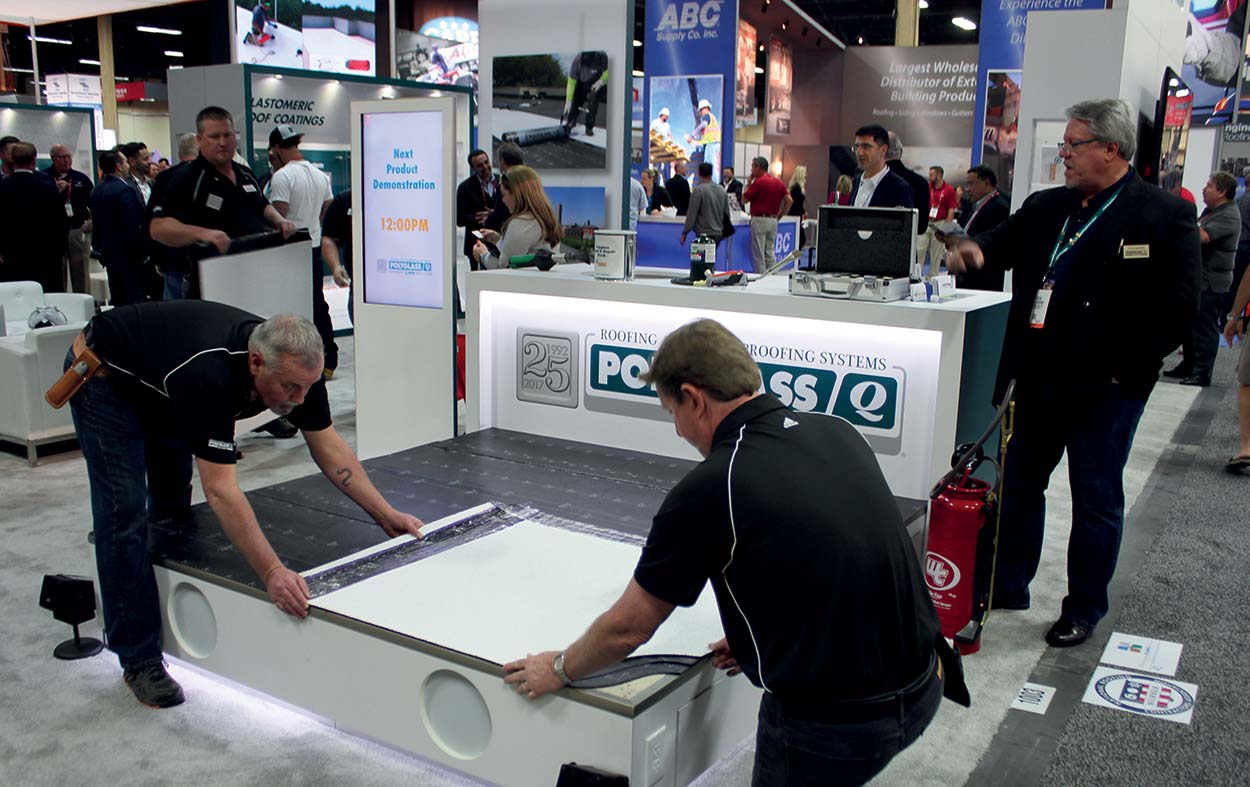

For Polyglass, their international outlook has always been in step with their approach to scientific research and their aim to constantly offer new solutions which are both simple and effective. And this is how their glass fibre support layer has been joined by non-woven polyester fabric, and traditional flame-applied membranes have been joined by the latest generation of self-adhesive membranes, which guarantee a high level of reliability during application.

In 1990, Polyglass developed ADESO® technology which enabled dual-compound, self-adhesive membranes to be produced, with an APP or SBS formulation on the top side and a highly adhesive formulation on the bottom side of the reinforcement.

A more recent introduction was CURE® Technology, a patented thin-film technology which increases energy efficiency, provides resistance to stains and UV rays and improves granule adhesion.

Polyglass has always firmly believed in the importance of respect for the environment and is committed to the research of products which improve energy efficiency and have a lower impact on the environment. Polyglass products can also help obtain credits for the LEED certification of buildings.

Constant growth in an expanding market

An interview with Natalino Zanchetta, CEO of Polyglass USA.

An Italian in America specialised in waterproofing membranes. Polyglass entered the American market, under your guidance, in the 1980s. How have you reacted to this challenge?

It was, and still is, an enormous challenge, but at the same time the overall experience has helped me mature and grow.

The difficulty has been to completely change my mentality and adapt to American culture and create products which are completely different to the standard products used in Italy and Europe. But this difficulty has helped in my growth and stimulated me towards innovation.

And that is what led to the development of Polyglass self-adhesive membranes; a major contributing factor as to why Polyglass USA has been so successful.

What is your outlook for the waterproofing membranes market in the United States?

The market is in constant expansion due to the increasing demand for bitumen and polymer-based membranes, particularly in the residential sector. The continuous modernisation of building codes is leading to an increase in the use of membranes, not only for roofs, but also as vapour and infiltration barriers for external walls and as acoustic barriers. The evolution of technology applied to the liquid membrane sector for repair work is constantly developing: and Polyglass USA is investing heavily in this particular field.

What are the future projects for Polyglass USA?

Polyglass USA has ambitious projects for the next 7 years and intends growing by 100% by the seventh year. We aim to reach this goal by maintaining our intense network covering all the territories of North America in the residential and industrial construction sectors, by commissioning a new production facility in Canada and by doubling the production of solid and liquid membranes in all our other production facilities over the next 10 years, particularly in the residential sector for the SOAR project.

How many facilities does the company currently have in the United States?

Polyglass has production facilities in Fernley (Nevada), Hazleton (Pennsylvania), Winter Haven (Florida), Phoenix (Arizona) and, by the end of 2017, there will be the new facility in Waco (Texas). Our head office is in Deerfield Beach (Florida), where we also have a Research Centre.