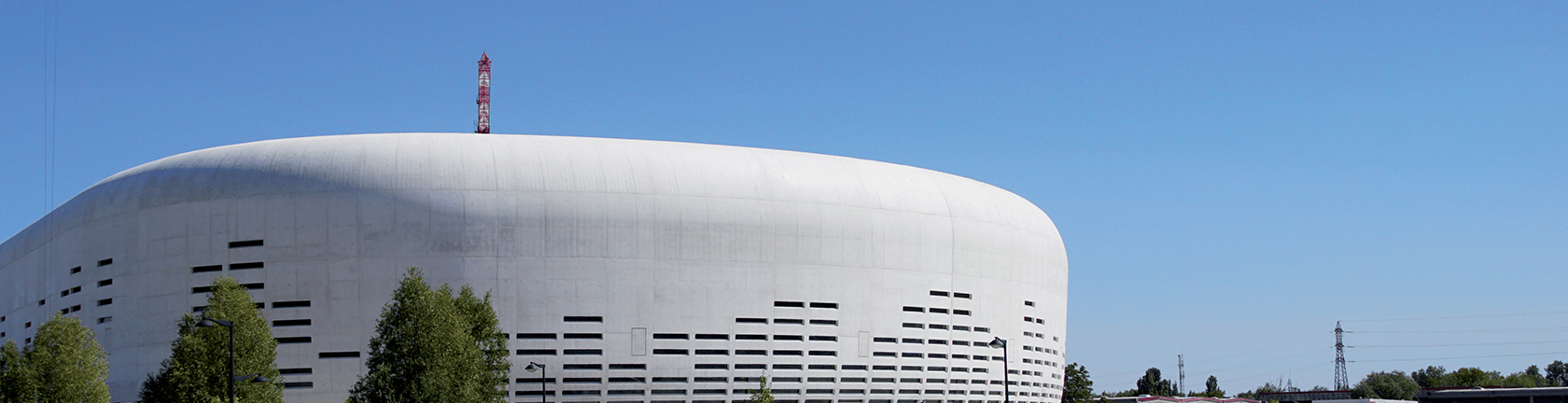

Arkea Arena, Floirac-Bordeaux (France)

The Arkea Arena is one of the most spectacular events venues in France and represented a design challenge from both a technical and aesthetic point of view: from the expert hand of the architect, Rudy Ricciotti, a smooth, compact surface was created, with forms both subdued and modern, moulded together using the poured concrete technique, rather than resorting to the usual metal, glass or ready-mixed concrete. Mortars and skimming compounds from Mapei’s NIVOPATE range played a decisive role in achieving such a result, while the final protection was achieved by applying ANTIPLUVIOL W impregnator.

Mapei Technical Services also played their part by proposing the PLANITOP line to repair concrete inside the arena and the MAPEFILL line for grouting and anchoring work, again inside the arena.

The building, which has been awarded prestigious HQ-Haute Qualitè certification, was designed according to the principles of sustainability, in line with Mapei’s best environmental policy.

The arena is considered one of the finest entertainment venues in France and its concrete shell posed quite a technical challenge.

The new Arkea entertainment hall in Floirac, a town in the Bordeaux Métropole area, was inaugurated in January last year. The Arena was designed by the architect Rudy Ricciotti and hosts around one hundred artistic and sporting events every year. Its construction proved to be quite a challenge from both an architectural and technical point of view and Mapei took part in the project by supplying various solutions and systems.

Right from the very start, the client and designer wanted the construction of the Arkea Arena to be a part of a more comprehensive project of sustainable development. First, priority was given to local employment, with more than 80% of the activity carried out by enterprises based in New Aquitaine region. Then, some of the construction materials were recycled or completely reconditioned: for instance, the formworks used to form the concrete shells were mainly recycled by transforming it mainly into fuel for biomass power stations, while the remainder was used to make panels. The structure was also awarded HQ (Haute Qualité Environmentale) certification, which promotes and rewards good performance levels in terms of energy consumption and environmental impact.

A TECHNICALLY SOPHISTICATED AND COMPLEX PROJECT

All the projects designed by the architect Rudy Ricciotti are a homage to concrete, a crude material that he loves so much and manages to exalt to the full: the MuCEM (Museum of European and Mediterranean Civilisations) in Marseille, the Jean Bouin Stadium in Paris and the Jean Cocteau Museum in Menton.

In the case of the Arkea Arena, Ricciotti has imaginated an enormous smooth, white pebble sitting on the banks of the River Garonne; an architectural form made up of curved lines, “perforated” by horizontal slits and illuminated at night by a LED lighting system. The main area in which shows and sporting events take place has been designed along the lines of an amphitheatre and has excellent acoustics. A system of motors allows the spectator stands to be retractable so their layout can be changed very quickly. The number of seats available varies from 2,500 to 11,300, depending on the type of event.

WHITE CONCRETE AT THE HEART OF THE PROJECT

Almost two years of work, 3 cranes operating at the same time on site, a workforce of 120, which increased to 200 in peak periods, 125,000 working hours and more than 10,000 m3 of white concrete placed. These are the figures of the technical and aesthetic challenges the main contractor had to tackle in order to build this curved concrete structure, with the same shade of white extending over its entire surface.

Most stadiums and arenas for entertainment events are covered with either metal or glass, whereas here the preference was concrete. As Ricciotti declared, "We could have built the Arena using precast concrete elements assembled on site, but we would never have been able to achieve the desired effect. And this is the reason why we relied on the more complex technique of using concrete cast on site”.

Even though the technique of casting concrete on site is undoubtedly a more complex option, it allows for better control of the final result. Formulated and supplied by Lafarge Beton, the white concrete was cast directly into 350 large wooden formworks designed especially for this site over a period of ten months.

In order to get a good final result and make sure the same shade of white was created over the entire surface of the building, Mapei France Technical Services recommended to use NIVOPATE FIN and coloured NIVOPATE FIN, which are manufactured and distributed on the French market by Mapei France. These products are smoothing compounds in paste which are mixed with cement or plaster. They are easy to apply in layers from 0 to 50 mm thick and it make the final colour homogeneous, depending on the type of binder used.

To complete the intervention on the shell, the white concrete surface (4.800 m2) was protected with ANTIPLUVIOL W, a colourless water-repellent impregnator based on silicon compounds in water solution.

To carry out minor repairs on the vertical and internal surfaces (stairways, walls and columns) of some precast concrete elements, it was recommended to apply PLANITOP 350 (class R2 semi-rapid-setting mortar), PLANITOP 450 (class R4 normal-setting mortar) and PLANITOP 400 F (class R3 rapid-setting mortar). All these mortars are manufactured and distributed on the French market by Mapei France.

Another technical challenge was the the metallic structure. In fact, the spectator stands in the Arkea Arena were also made from cast concrete. The roof is supported by a structure with two main beams, with one of them 55 m in length and the other 82 m in length. To lift the beams and the sections of the framework, a 700-ton crane was required, and it took a whole month to assemble it inside the Arena. While the other cranes were positioning the last formwork, MAPEFILL F high-performance mortar was used to anchor and seal the metallic structures and pre-cast concrete stairs in place.

This article was taken from Mapei & Vous no. 48, the in-house magazine published by Mapei France, whom we would like to thank. For further information see www.mapei.fr.

.jpg?sfvrsn=e23ae275_6)

.jpg?sfvrsn=e33ae275_6)

.jpg?sfvrsn=ec3ae275_6)

.jpg?sfvrsn=d73ae275_6)

.jpg?sfvrsn=d43ae275_6)

.jpg?sfvrsn=d53ae275_8)

.jpg?sfvrsn=d63ae275_6)