Apollo Theatre

The historical theatre of this Apulian city in Southern Italy has been reopened after lengthy restoration work.

100 years after its inauguration in 1912, the Apollo Theatre was reborn: after being shut down in the 1980'8, this gem could not shine in glamour anymore until the local council issued a tender in 2007 to save it. Mapei was on the spot, giving its assistance and specific systems for static consolidation, wooden and textile floorings, substrates preparation and renovation in general.

After being closed for 30 years, and a 8 year restoration intervention costing 12 million Euros, the Apollo Theatre in Lecce was reopened this year at the beginning of February in the presence of Italy’s President of the Republic, Sergio Mattarella, and of the Minister for Culture and Tourism, Dario Franceschini.

The inaugural evening, under the artistic direction of Katia Ricciarelli, famous in Italy as former soprano and actress, and directed by Pierluigi Pizzi, kicked off with the Italian National Anthem and the Ode to Joy from Beethoven’s Ninth Symphony performed by the Tito Schipa Symphony Orchestra of Lecce conducted by Maestro Gianluigi Gelmetti and the Opera Choir of Lecce conducted by Maestro Emanuela Di Pietro. The guest of honour was the actor Giancarlo Giannini, who told the story of the Apollo Theatre.

A CENTURY-LONG STORY

Located in the old part of the centre of Lecce, the Apollo Theatre is considered one of the most important monuments of this Apulian city. Its current structure dates back to the early 1900’s when the owner, Vincenzo Cappello, who had been granted use of a stretch of land along Via Trinchese, decided to build a theatre in that very spot. Up until the 1980’s, when it closed its doors for the last time, the main hall had been used for concerts, operas, variety shows and as a cinema.

In 2007 the local council issued a tender to restore the theatre and, around 100 years after its inauguration in 1912, the Apollo Theatre was reborn.

From the outside, the theatre is characterised by its Neo-classical style, with an architrave sitting on an imposing row of columns. The inside of the theatre is decorated in Hellenistic style, with Murano glass lampshades and wall-lights and wooden columns.

When the theatre is featuring operas, classical music and other shows it can seat 719 spectators, with 477 in the stalls, 184 in the two rows of boxes and 58 in the gallery. There is also a conference hall at gallery level with seating for up to 90 people. The stage is mobile and has a 25 meter scenery tower, while the orchestra pit can house up to 60 musicians. The designers opted for pale shades to decorate the theatre, playing on a colour scheme of brown, grey, white and beige, and chose to get rid of the red stage curtain.

It was also decided to renovate the characteristic zinc cupola, which at the start of the last century was mobile. The upper part of the foyer has been decorated with an archaeological pathway along which the various finds unearthed during the work are exhibited.

CUTTING-EDGE TECHNIQUES AND COMPOSITE MATERIALS

Mapei Technical Services carried out a series of technical surveys on site, followed by an in-depth analysis of the various problems they had found.

Work started with the static consolidation of all the Leccese stone pillars on the ground and first floors and of the pillars in Carparo stone (both typical types of limestone from the Apulia Region) on the second floor and of the concrete pillars of the last floor.

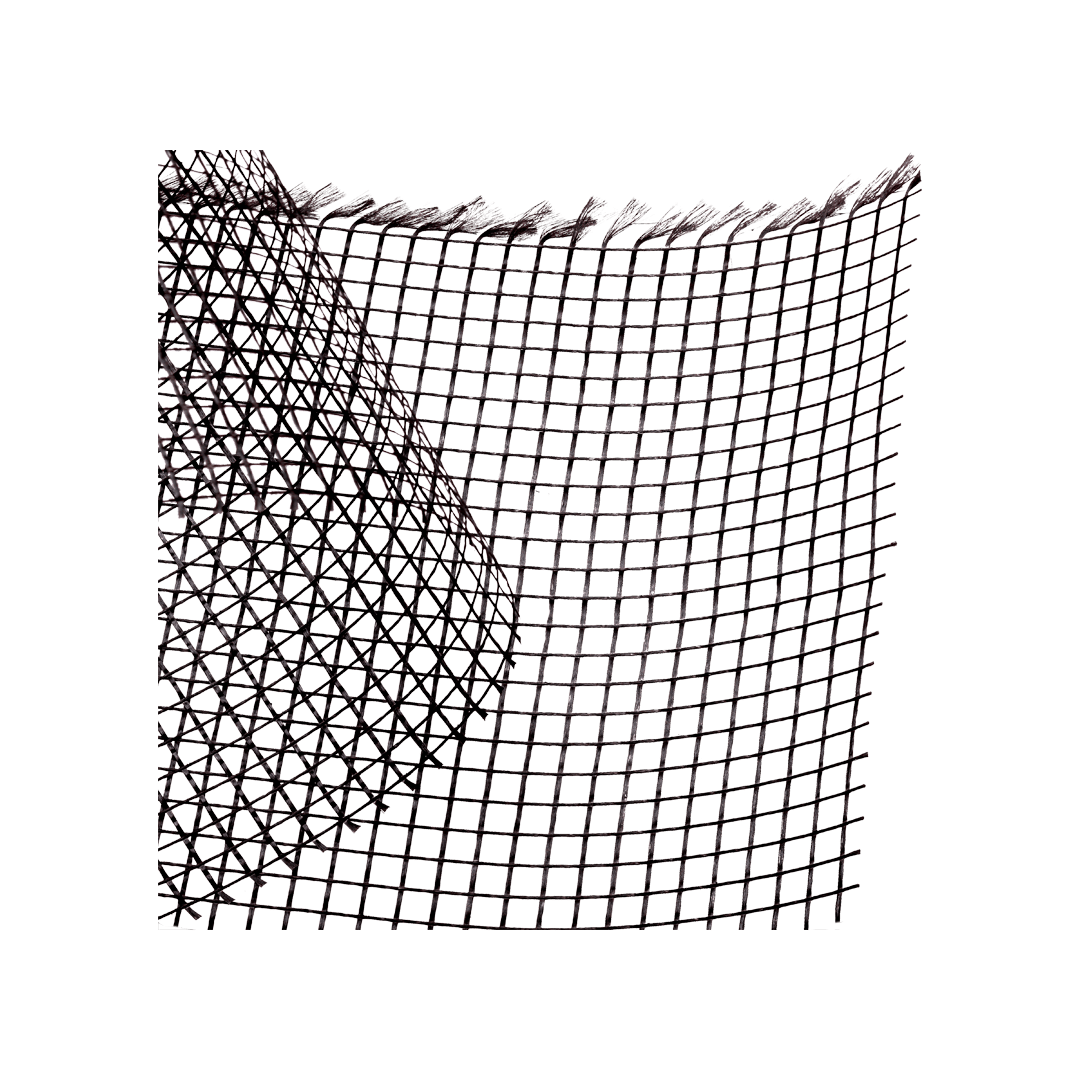

The concrete pillars on the 2 upper floors, which during the site survey were found to have structural problems, were statically confined with a system comprising PLANITOP HDM MAXI cementitious mortar with Pozzolanic-reaction binders and MAPEGRID G 120 alkali-resistant glass fibre mesh, which is used to provide localised reinforcement for masonry and concrete substrates.

Choosing composite materials proved to be decisive from a structural point of view for several reasons: there is only slight increase in weight and, as a result, overall mass is hardly affected, this strengthening technique is sustainable, is non-invasive and is compatible with renovation work aimed at safeguarding historical and monumental structures of this kind, the materials used are durable over the years and are characterised by high mechanical performance characteristics and, finally, this type of strengthening system, using PLANITOP HDM MAXI mortar, is extremely reliable and is easy to apply and work with.

WORKING ON AN HISTORICAL BUILDING

To carry out the restoration work the contractor used various building materials, including special U-shaped profiles which were welded to the old steel annular beams on the first three floors. This was followed by the application of a layer of MAPEFILL ready-mixed mortar with high-strength cement and special additives, including an expansive agent to completely eliminate the risk of shrinkage during the plastic phase and once the mortar had hardened.

To fill all the cracks, gaps and internal cavities between the Leccese and Carparo stone elements, including the larger ones, and to consolidate the Leccese stone pillars on the ground and first floors and the Carparo stone pillars on the second floor, the product recommended was MAPE-ANTIQUE I fillerized, super-fluid, lime and Eco-Pozzolan based hydraulic binder. This product was proposed because, once hardened, slurry made from MAPE-ANTIQUE I has very similar characteristics in terms of mechanical strength, modulus of elasticity and porosity to mortar made from lime, lime-Pozzolan or hydraulic lime originally used for the construction of historical buildings.

THE IMPORTANCE OF CONSOLIDATION WORK

Static consolidation of the beam below the cupola, and between the concrete pillars and the floor slab in the stalls area, was carried out using Mapei systems, and in this specific case, MAPEFER two-component, anti-corrosion cementitious mortar to protect the rebar that had previously been exposed and brought to a bare metal finish, and MAPEGROUT THIXOTROPIC fibre-reinforced, shrinkage-compensated cementitious mortar, which is used to restore deteriorated concrete.

Static consolidation of the annular beams between the pillars was carried out with MAPEFER to passivate the metal elements and MAPEGROUT HI-FLOW shrinkage-compensated mortar to reintegrate the concrete.

In the stalls area on the ground floor, Mapei Technical Services recommended to the contractor to apply a de-humidifying system comprising MAPE-ANTIQUE RINZAFFO breathable, salt-resistant, lime and Eco-Pozzolan scratch-coat mortar and MAPE-ANTIQUE MC macro-porous, de-humidifying, rendering mortar, which is used to renovate old masonry.

For the areas without rising damp – the foyer, the remaining part of the stalls and the intrados of the floors in the gallery – the product used was MAPE-ANTIQUE INTONACO NHL breathable, natural hydraulic lime and Eco-Pozzolan base mortar, which is recommended for new and existing masonry, including in buildings of historical interest, such as in this particular case.

For the two main concrete stairways leading to the boxes, the service areas below the foyer and the dressing rooms under the stage, the product used was INTOMAP R1 aerated lime and hydraulic lime based base render, while PLANITOP 530 fine-textured mortar for render and concrete and PLANITOP 560 ultra fine-textured mortar for render were used to smooth the relative areas of lime-cement based surfaces.

INSTALLATION OF WOODEN AND TEXTILE FLOOR AND WALL COVERINGS

The internal floors in the Apollo Theatre (around 1,200 m2 in total, including the heated floors in the stalls, the 48 boxes, the gallery and the various connecting stairways) were also renovated.

The design included a heated screed with underfloor heating for the stalls area made from TOPCEM PRONTO ready-mixed, normal-setting, controlled-shrinkage mortar, which is used to make rapid-drying screeds.

The existing screeds in the boxes were restored and consolidated with PROSFAS solvent-free consolidator with high penetration capacity for cementitious substrates. It helped improve the adhesion between the new render carried out with TOPCEM PRONTO and the old existing substrate. EPORIP epoxy adhesive was used to seal the cracks.

Once work on the installation substrates had been completed, the wooden flooring was installed. The first step was to waterproof all the surfaces with ECO PRIM PU 1K solvent-free, moisture-hardening primer with very low emission of volatile organic compounds (VOC). For the stalls and the three floors of the theatre, including the boxes, oak floorboards (measuring 1,830mm x 129mm x 22mm) were installed with ULTRABOND ECO S955 1K solvent-free, silylated polymer-based adhesive with very low emission of volatile organic compounds (VOC), which is suitable for use with heated floors, while for the flooring on all the stairways, again in oak, ULTRABOND P902 2K epoxy-polyurethane adhesive was the preferred choice.

The polyester textile wall coverings for the boxes were bonded in place with ADESILEX MT 32 adhesive in water dispersion, which is ideal for installing wall coverings.